Math and system design software for multidisciplinary product development. In addition to the desktop software solutions, Altair democratizes simulation offering instant-on cloud access, lowering the barrier of entry for organizations with limited IT and compute resources to drive their design process with simulation. Leveraging the Altair ® Inspire ™ robust solution set for model-based development, concept design, multiphysics, and manufacturing simulation early and often has become a key driver to innovation and is helping numerous industry-leading companies to meet quality, cost, and time to market targets.

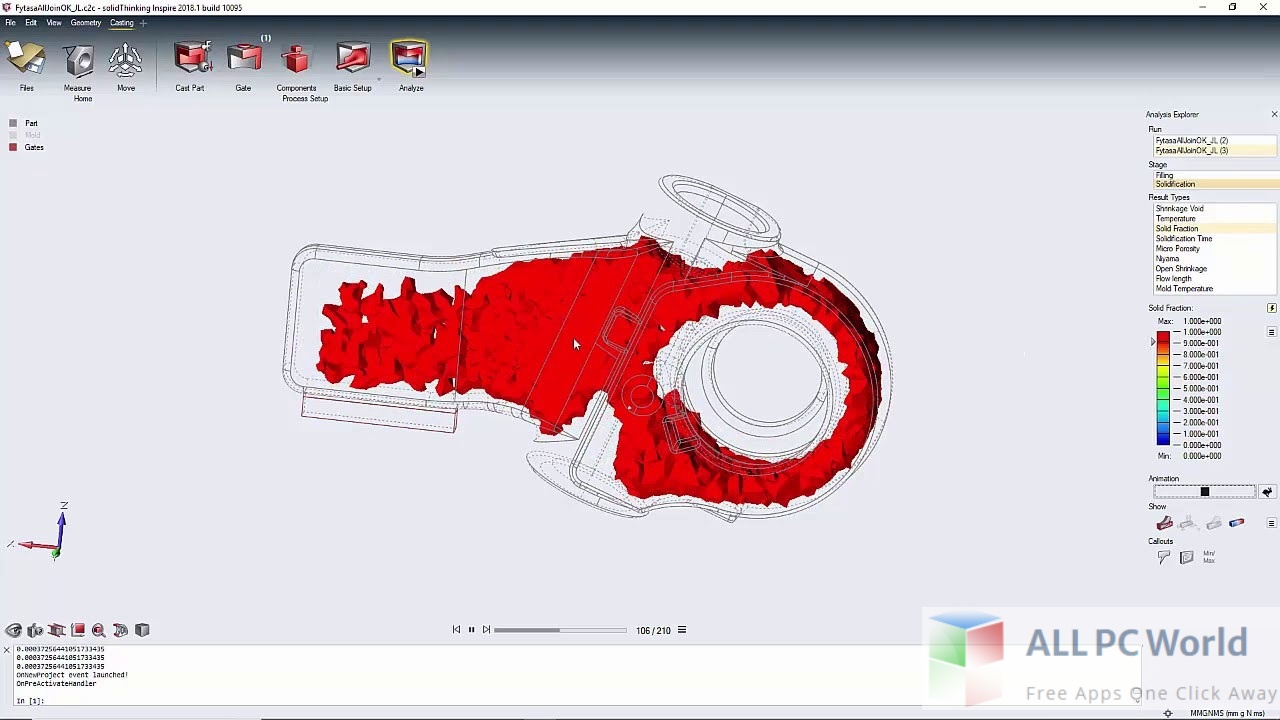

Honda Engine Meshless CFD Particle Method Analysis.See all Case Studies in the CAE Knowledge Library.This software can simulate at high speed because it creates a simulated model in just five steps. This software helps users to identify and correct possible defects, such as defects due to liquid flow, such as cold welding, air inclusions, inclusions of inclusions and slag, and defects due to freezing, including large voids, small voids, gas gaps, residual stresses, cracks.

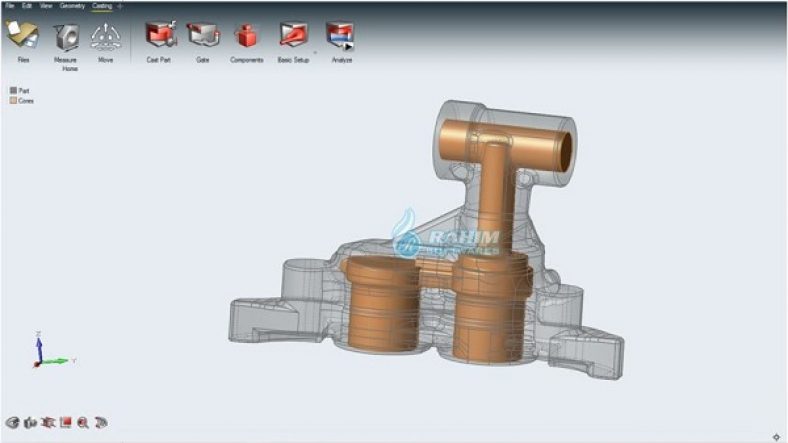

This process is the oldest known process for obtaining the desired shape of metals.Īltair Inspire Cast, previously published as solidThinking Click2Cast, is simulation software that is a casting process that provides a simple but functional environment for creating and optimizing production parts. Altair Inspire Cast’s innovative experience enables users to improve product quality and develop better products with just a few hours of training.Ĭasting is the art of shaping metals and alloys by melting, pouring the melt into a chamber called a mold, and then cooling and solidifying it according to the shape of the mold chamber.

Guided Process Templates offer 5 simple steps to simulate gravity nozzle, gravity sand, investment material, high pressure die casting, low pressure and inclined casting. It is the only tool that appeals to both beginners and experts, from product designers to foundry engineers.Įven in the initial design phase, users can visualize typical casting defects, such as air inclusions, shrinkage porosity, cold connections, and shape deterioration, and correct them without costly post-correction. Altair Inspire Cast 2021 software is a fast, simple, accurate, and affordable casting simulation environment that focuses on producing high-quality components more cost-effectively through a highly intuitive user experience.

0 kommentar(er)

0 kommentar(er)